This project is subdivided into 7 work packages:

Work Package 1: Carbon Capture and a decision support tool

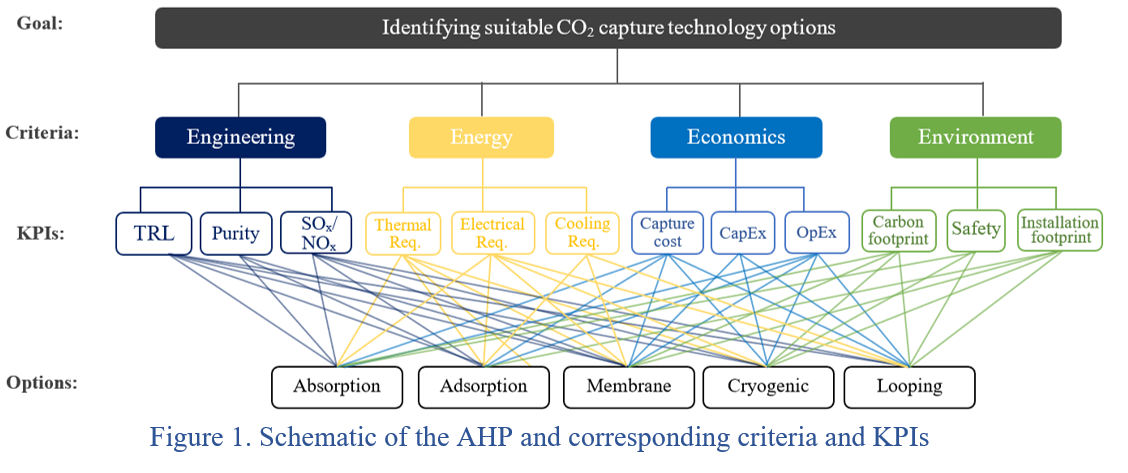

Selecting an appropriate CO2 capture (CC) technology is a complex task, given the diverse range of available CC technologies and their varying technical, economic, and environmental performance. Despite extensive literature, the absence of a standardized cost estimation methodology makes it difficult to compare technologies fairly across studies. To address this, WP1 of the PROCURA project developed a structured framework based on four criteria: Engineering, Energy, Economics, and Environment. These are supported by Key Performance Indicators (KPIs), including Technology Readiness Level (TRL), CO2 capture cost, and environmental footprints, among others.

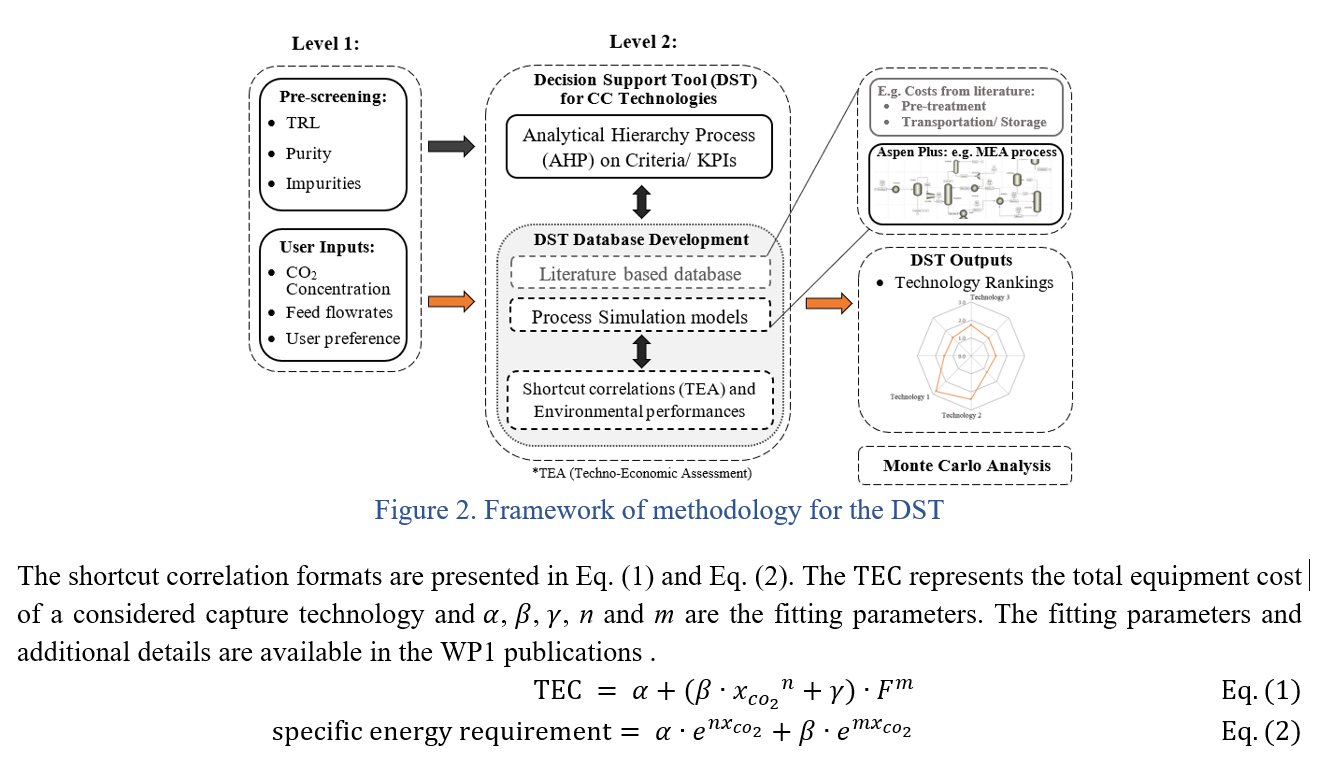

Also, shortcut correlations were developed to bridge the gap between detailed process simulations and practical decision-making. These correlations link flue gas characteristics such as CO₂ concentration and flow rate to key technical and economic metrics, enabling rapid, consistent, and scalable assessments across capture technologies. These results have been integrated into a Decision Support Tool (DST), allowing stakeholders to screen and rank capture technologies according to process conditions and user-defined preferences, supporting consistent and informed decision-making. A simplified, web-based version of the DST, also referred to as SCAN-CC (Systematic Comparison & AssessmeNt for Carbon Capture), is currently under development to make the tool more accessible to technical and research communities.

Goals and Objectives

To support informed and transparent decision-making, the DST evaluates CO₂ capture technologies using a structured hierarchy of criteria and key performance indicators (KPIs). As shown in Figure 1, the overall goal is broken down into four main criteria: Engineering, Energy, Economics, and Environment, each connected to relevant KPIs.

The overall goal and objectives of this work are as follows:

• Develop a DST based on the Analytical Hierarchy Process (AHP) with a double-weighted matrix to support structured and transparent CC technology selection.

• Integrate shortcut correlations, developed from detailed simulations and literature data, into the DST database to ensure fast and accurate cost and technical performance estimates for advanced CC technologies (TRL > 6).

• Demonstrate the applicability of the DST through industrial case studies, providing clear recommendations for technology selection across different sectors.

Methodology and DST framework

The process begins with a pre-screening step based on technology maturity, purity, and impurity tolerance, followed by user inputs such as CO₂ concentration, flow rates, and preferences. These inputs feed into the DST, which uses the AHP and a database built from both literature and validated process simulations. Shortcut correlations are used to estimate performance metrics. The final output is a ranked list of capture technologies tailored to user-defined criteria and gas conditions. Lastly, Monte Carlo simulation is used to test how changes in user-defined preferences (AHP weights) affect results. This helps identify whether technology rankings remain stable or shift under uncertainty.

Main Results

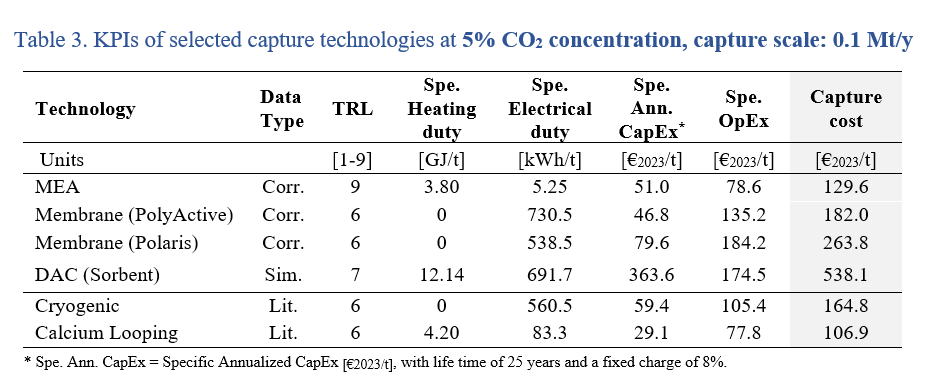

This case study features a Belgian industrial plant with a low CO₂ concentration (5%) and a capture scale of 0.1 Mt/y. Capture costs are estimated using shortcut correlations (Corr.) for MEA and membrane technologies, with TEC converted to CapEx using the DOE/NETL method. For this example, Selexol was not evaluated using correlations due to its limited suitability at low CO₂ concentrations, but was still included in the DST with low performance scores, resulting in lower rankings. DAC results (refer to WP1 publications) are based on in-house simulation (Sim.) and techno-economic analysis developed in WP1, while literature data (Lit.) is used for cryogenic and calcium looping. Main KPIs are summarized below.

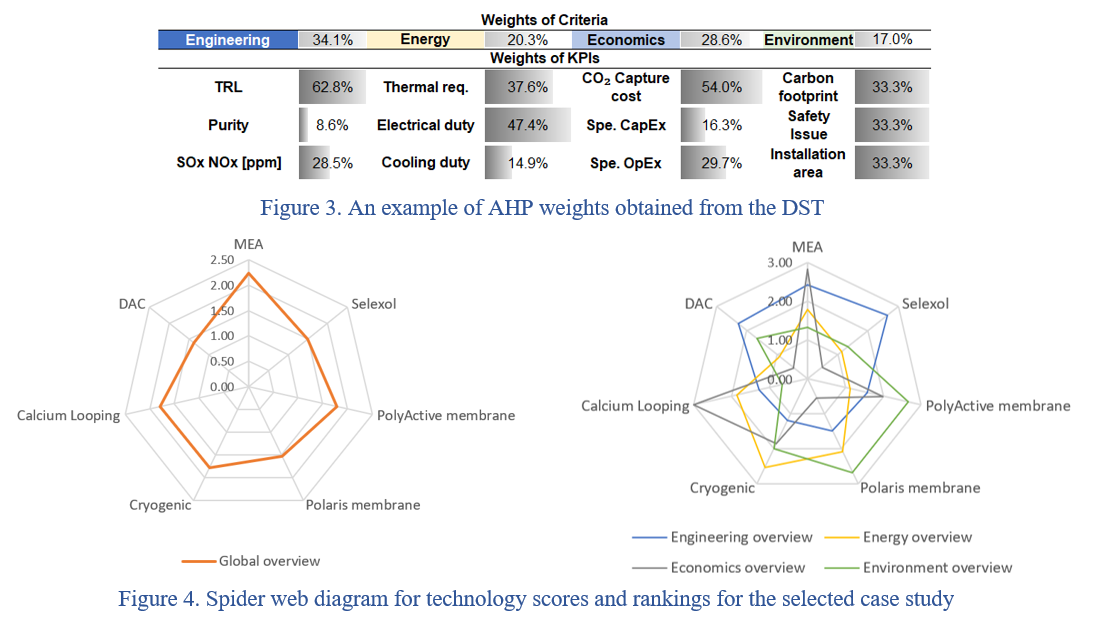

To demonstrate the DST, user-defined preferences were applied through the AHP method (Figure 3), prioritizing engineering (34.1%), with a strong focus on TRL (62.8%). High weights were also given to electrical duty (47.4%) under energy and capture cost (54.0%) under economics. Environmental KPIs were equally weighted. Based on these weights, the DST ranked technologies for the case study described above (Figure 4).

The DST results highlight key differences in capture technology performance based on user-defined weights. MEA ranks highest overall, driven by strong engineering and economic scores, followed by PolyActive membranes and calcium looping. While membranes perform well environmentally, they face economic challenges at low CO₂ concentrations. DAC and cryogenic technologies rank lower due to high energy use and low TRL. Monte Carlo simulations, using 10 000 different weight combinations, confirmed that MEA (100% of runs) and PolyActive (90% of runs) consistently ranked at the top, while DAC and Selexol remained lowest. These results show that some technologies are more sensitive to changes in user preferences. Overall, the analysis reveals key trade-offs between technical, energy, economic and environmental performance in a systematic framework.

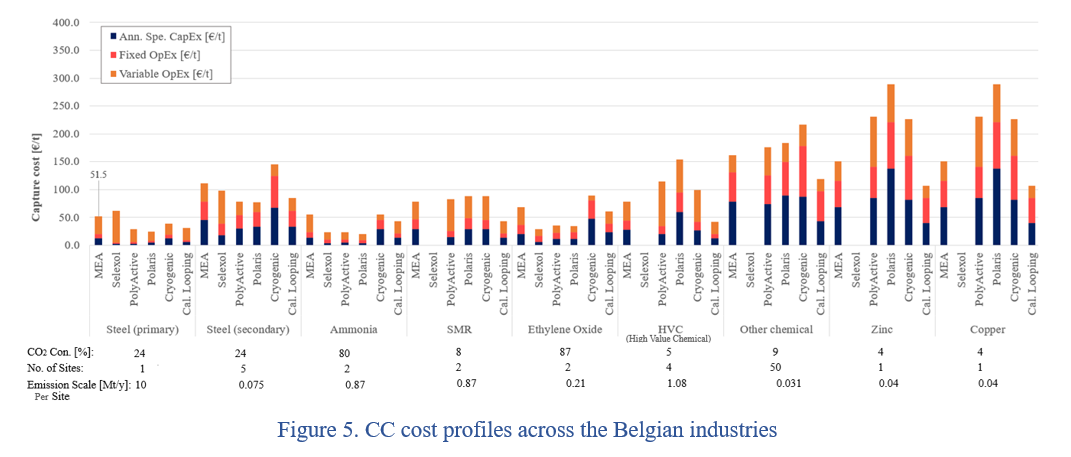

Using Belgian industry emission profiles, WP1 shortcut correlations can be applied to identify cost-effective CC options. An example of capture cost profiles is shown in Figure5.

Conclusion and Perspectives

• Selecting the right CC technology is inherently complex, not only due to trade-offs in technical, economic, energy, and environmental performance, but also because these performances depend on site-specific flue gas characteristics such as CO₂ concentration and flow rate.

• The DST provide a structured, KPI-based approach to support informed and consistent decision-making (a simplified web-based DST is currently under construction).

Perspectives

• Expand technology scope: Include CC options like potassium carbonate and hybrid systems.

• Broaden assessment boundaries: Integrate pre-treatment, transport, storage costs, and social/ environmental impacts (e.g., via LCA).

• A spin-off is planned to support industry adoption through expert consulting with the SCAN-CC tool.

Contact Information

• The University of Liege: Department of Chemical Engineering

• If you have any questions, please don't hesitate to reach out to sm.kim [at] uliege.be (So-mang Kim) (ULiege) or g.leonard [at] uliege.be (Grégoire Léonard) (ULiege).

Publications

Kim, S. and Léonard, G., 2025. CO2 capture technologies and shortcut cost correlations for different inlet CO2 concentrations and flow rates. Part 1: Chemical absorption. International Journal of Greenhouse Gas Control, 145, 104391. https://doi.org/10.1016/j.ijggc.2025.104391

Kim, S. and Léonard, G., 2025. Short-cut correlations for CO₂ capture technologies in small-scale applications, ESCAPE 35 – European Symposium on Computer Aided Process Engineering, System & Control Transactions, Volume 4. July 2025.

Kim, S., Salman, M. and Léonard, G., CO₂ capture technologies and shortcut cost correlations for different inlet CO₂ concentrations and flow rates. Part 2. Physical Absorption and Membrane Processes, [Manuscript under internal review. Planned submission before the end of 2025].

Kim, S. and Léonard, G., Evaluation of Belgian industrial case studies using shortcut correlations and a decision support tool for carbon capture technology screening. [Planned submission before the end of 2025].

Kim, S. and Léonard, G., 2023. Optimization of large-scale direct air capture (DAC) model using SCR algorithm, ESCAPE 33 - European Symposium on Computer Aided Process Engineering, 52, pp. 1181–1186.

Kim, S. and Léonard, G., 2022. Performance and sensitivity analysis of direct air capture (DAC) model using solid amine sorbents for CO₂ capture, GHGT-16 – Greenhouse Gas Control Technologies Conference, 23–24 October 2022. Available at: https://ssrn.com/abstract=4280585

Kim, S., Salman, M. and Léonard, G., 2022. Application of decision support tool (DST) based on analytical hierarchy process for screening of carbon capture technologies. GHGT-16 – Greenhouse Gas Control Technologies Conference, 23–24 October 2022. Available at: https://ssrn.com/abstract=4280591

Kim, S. and Léonard, G., 2022. Process modelling of direct air capture (DAC) of CO₂ using solid amine sorbents, ESCAPE 32 - European Symposium on Computer Aided Process Engineering, 51, pp. 265–270.

Work Package 2: Power to chemicals

In this part of the PROCURA project, the role of e-molecules has been investigated. Unlike their fossil counterparts, these molecules are produced from renewable energy sources. One of the most straightforward examples is ammonia production, which is typically based on H2 produced from natural

gas (leading to large amounts of GHG emissions), but this can be replaced with H2 produced from water electrolysis coupled to renewable energy. For CO2-based molecules, the same principle applies. These molecules are often important base chemicals but are also increasingly considered for a role as

synthetic fuel, to decarbonize transport modes that are hard to electrify (e.g. shipping, aviation).

As the first objective of the project, the economics behind the production of such molecules have been investigated. It was found that they are usually several times more expensive than their fossil counterparts, which impedes the spontaneous roll-out of these technologies. Often, the energy and capital cost for the water electrolysis will be the most important cost factor. When considered from a life cycle perspective, the production of these molecules usually leads to a reduction of greenhouse gas emissions compared to the business-as-usual scenario, at least if sufficiently low-carbon electricity

is used. In carbon-based fuels such as methanol, an important distinction to be made is whether the CO2 is of fossil (e.g. cement production) or biogenic (e.g. biogas) origin. Only in the latter case can the value chain be entirely climate neutral if the molecules are used as fuel, where the CO2 is liberated

again upon use. This aspect is also increasingly reflected in EU policy.

Generally speaking, the more conversion steps needed to reach the target molecule, the lower the overall energy efficiency. This is particularly apparent when ammonia is not used as such but intended as an H2 carrier to transport renewable energy from locations with favorable conditions to locations

which are net importers of energy. An economic analysis showed that the H2 derived from imported ammonia would be ~4 times more expensive than the renewable energy from which it was made remotely.

Several policy initiatives exist, both at Belgian (cfr. Hydrogen strategy) and European (cfr. Renewable Energy Directive) level, to promote the production, import and consumption of e-molecules. These range from establishing partnerships with countries that could be net exporters of e-molecules to setting hard targets for shares of e-fuels in total energy use. Particularly for aviation fuels, ambitious long-term targets have been set (35% in 2050 as per the Refuel EU aviation initiative). Despite these various stimuli, a review of projects indicates that many e-molecules projects have been cancelled (both in Belgium as well as other EU countries). The future production level of such e-molecules

remains a point of debate and may not reach large volumes in a country like Belgium that has limited endowments of renewable energy. As modelling in other work packages in the project showed, it may depend on imports of green hydrogen via pipeline as well as the cost and feasibility of alternative

decarbonization pathways like applying carbon capture and storage.

Contact information

If you have any questions, please don't hesitate to reach out to metin.bulut [at] vito.be (Metin Bulut) (VITO) or pieterjan.debergh [at] vito.be (Pieterjan Debergh) (VITO).

Full report

Would you like to read the full report? Click here.

Work Package 3: Power to energy

Belgium's commitment to climate neutrality by 2050 requires deep transformation of its energy systems, prioritizing the adoption of renewable sources, electrification, and carbon-neutral technologies. The PROCURA project Work Package 3 (WP3), part of the Energy Transition Fund, sponsored by the FPS Economy of Belgian and led by VITO/EnergyVille, explores the role of Power-toX (PtX) and Carbon Capture, Utilization, and Storage (CCUS) in supporting this transition. Utilizing the TIMES-BE energy system model, the project investigates different future scenarios and their implications for energy production, demand, infrastructure, and policy. The main objective of the energy system model is to optimise the entire energy sector of Belgium in function of lowest system cost for society, whilst meeting the stringent CO2 reduction targets required to match net-zero by 2050.

The study defines four contrasting energy transition pathways: EVOLUTION, ACCELERATION, AMPLIFICATION, and TRANSFORMATION. These represent varying levels of ambition in terms of technology rollout, societal engagement, geopolitical developments, and regulatory support. All scenarios achieve the net-zero emissions target by 2050, yet they follow markedly different trajectories. ACCELERATION emphasizes rapid deployment of hydrogen infrastructure and early adoption of small modular nuclear reactors (SMRs), while AMPLIFICATION hinges on widespread public engagement and full deployment of renewable energy potential. The TRANSFORMATION pathway envisions a future where clean molecule markets mature rapidly, reducing dependency on fossil fuels and enabling full-scale industry decarbonisation.

Electricity demand rises across all scenarios due to sectoral electrification. Smart charging and vehicleto-grid (V2G) systems are essential to integrate growing volumes of variable renewable energy, particularly from wind and solar. By 2040, as many as two million heat pumps could be installed in Belgian households, supported by renovation efforts. Commercial and industrial sectors also begin adopting heat pumps and electric boilers, with thermal energy storage improving system flexibility. Industrial decarbonisation focuses on electrifying low and medium-temperature heat applications, while high-temperature processes, such as steel and chemical production, rely on CCUS or clean fuels. In the most ambitious scenarios, these sectors move toward electric furnaces and electrochemical processes.

Transport undergoes a major shift, with road transport almost fully electrified by 2040. Smart charging and Vehicle to Grid (V2G) not only reduce peak demand but also enhance system flexibility, helping accommodate higher shares of renewables. However, hard-to-electrify sectors like aviation and maritime rely mainly on imported synthetic fuels, including ammonia and e-methanol. This reinforces the need for robust infrastructure at ports and airports and highlights Belgium's strategic role as a clean fuel hub for Europe.

Short-term electricity storage, especially through batteries and electric vehicles, is prioritized over seasonal storage of molecules. Clean molecule power plants are used primarily during peak demand periods, with limited utilization due to high costs and competition from battery solutions. As Belgium integrates more deeply into the European electricity grid, cross-border electricity trade replaces the need for extensive domestic seasonal storage. Nonetheless, imported clean fuels will remain essential for specific industrial and transport sectors.

The TIMES-BE model demonstrates the importance of early, coordinated action. From now until 2035, focus must be on "no-regret" strategies: accelerating electrification of low-temperature heat, expanding EV infrastructure, deploying smart charging, and upgrading the electricity grid. Investment in offshore wind and HVDC connections to neighboring countries is critical to ensuring a steady supply of low-carbon electricity. For industry, early CCUS deployment in sectors such as cement and lime is vital, as are clear carbon pricing signals and public-private partnerships.

Beyond 2035, high-temperature heat and process emissions become the primary challenges. Here, support for innovative technologies like electric furnaces and synthetic fuels will be essential. Direct electrification remains the most energy-efficient path where possible, but hydrogen and PtX will be necessary for specific cases. As Belgium has limited renewable potential, international partnerships for clean molecule imports must be established, and infrastructure for handling and transporting these fuels should be developed.

In a nutshell, the out outcome of the using energy system investment models such as TIMES-BE, highlights that while multiple pathways to decarbonization exist, robust planning, public engagement, infrastructure investment, and technological innovation will determine success. The most prudent approach involves prioritizing scalable, cost-effective actions that deliver benefits, or no regret investments under any scenario. This includes energy efficiency improvements, electrification, strategic imports, and flexible electricity systems. These foundations will allow Belgium to adapt to emerging challenges and maintain momentum towards a net-zero future.

Contact information

If you have any questions, please don't hesitate to reach out to joris.valee [at] vito.be (Joris Valee) (VITO) or juan.correalaguna [at] vito.be (Juan Correa Laguna) (VITO).

Full report

Would you like to read the full report? Click here.

Work Package 4: Solar fuels

KU Leuven conducted a comprehensive mapping of existing solar fuel technologies. Next to the more ‘conventional’ high TRL-level approach based on PV + electrolysis, solar fuel technologies were classified into four primary categories: solar thermochemical (ST), photo-catalytic (PC), photobiological (PB) and photoelectrochemical (PEC) approaches. Besides these ‘pure’ solar fuel approaches, a hybrid approach defined as ‘integrated PV-electrolysis’ (iPVEL) was also considered. These systems skip the direct semiconductor-liquid interaction altogether by combining a conventional PV module with a novel electrolysis device type, bridging the conventional electrolysis and ‘pure’ solar fuel processes. For each of these categories, KU Leuven analyzed the underlying principles, technology readiness level (TRL) prognosis, and current state of development. The assessment included a review of international research initiatives, commercial activities, and pilot-scale implementations including Synhelion, Solhyd, SoHHytec, Photanol, Fusion Fuel, Brineworks, Oxylum, Heliogen, Lightfuel and H2Hysun.

Following the technology mapping, KU Leuven selected key solar fuel technologies for in-depth analysis based on their potential relevance for Belgium and their projected technological evolution. The main candidates included photoelectrochemical water splitting and solar thermochemical fuel production.

For each selected technology, KU Leuven conducted a detailed techno-economic analysis. This involved identifying process characteristics (e.g. efficiency, materials requirements, energy input), evaluating capital and operational expenditures, and analyzing potential cost trajectories over time. A key insight from this analysis was that while some solar fuel technologies show promising long-term potential (2040 onwards), they currently remain less mature and more costly than electrolysis-based approaches. The hybrid iPVEL approach could be commercially competitive from 2030 onwards.

KU Leuven also performed sensitivity analyses to assess how variations in key parameters — such as solar irradiance, material costs, and system efficiency — would affect the overall feasibility of each technology. The results indicated that while solar thermochemical and photobiological approaches offer unique advantages, such as high energy density fuels or the ability to produce complex chemicals, their large-scale deployment in Belgium is currently limited. This is mainly due to constraints related to land use and the relatively low intensity of direct sunlight in the region. In contrast, photoelectrochemical and integrated PV-electrolysis systems showed strong potential for decentralized hydrogen production in Belgium on a shorter term (towards 2030), particularly when combined with emerging high-efficiency tandem solar cells. These technologies may be well-suited for local energy networks and applications where compact, modular systems are an advantage.

Finally, the data collected on solar fuel technologies in T4.2 and T4.3 was translated into a dataset enabling to incorporate the different solar fuel technologies into the TIMES-BE model used for scenario development in WP3. Given the low TRL level of most technologies and the scarcity of available data, an alternative approach was adopted to estimate the different parameters. This approach involved setting up a database of > 80 scientific publications, product and process specification sheets, etc. and feeding this into an AI model. After a series of iterations and extrapolations, a first parameter set was obtained for solar thermochemical, photobiological, photocatalytic and photoelectrochemical solar fuel technologies, factoring in the different process configurations, output products and potential future improvements. The iPVEL approach was not included in this exercise as it is a not a pure solar fuel approach. An example of the dataset for ‘solar thermochemical technology with syngas output’ that was implemented in the TIMES-BE model, is shown below. The other datasets are available on the PROCURA website.

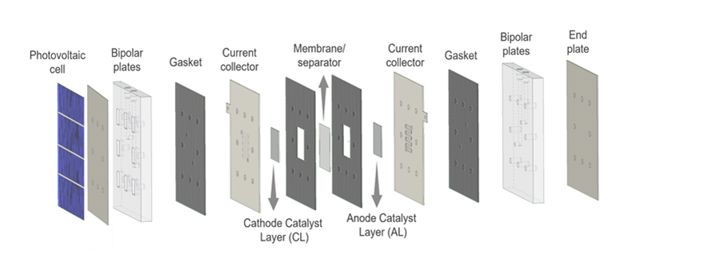

A whole new design was developed for this (Fig. 4.1), taking into account that electrode connections and other wiring, feedthroughs and piping should no longer be positioned on the front or backside of the electrolyzer element to allow a clean and flat surface to be available to attach the PV module directly on the electrolyzer element. Therefore, connectors etc had to be brought to the sides of the electrolyzer element. On Fig. 4.2a, the PV module is depicted, to be attached to the front of the electrolyzer element.

Fig. 4.1: Exploded view of the novel advanced electrolyzer design; on the left side the PV element is represented, to be directly attached at the front of the electrolyzer

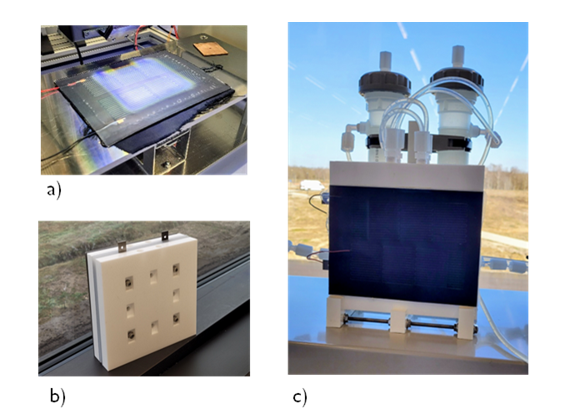

Fig. 4.2: The PV-integrated electrolyzer realized, with a) the CIGS PV module or test illumination, b) the 20cm by 20 cm newly designed electrolyzer element, and c) the completed assembly

The actual realization of this PV-integrated electrolyzer system is demonstrated with pictures in Fig. 4.2b & c. A thin-film, lightweight CIGS solar cell (CIGS = Copper-Indium-Gallium-Sulfur) assembly was selected to act as PV power source. The assembled electrolyzer element with a size of 20cm by 20 cm. Finally, the fully assembled PV-integrated electrolyzer set-up, whereby the dark blue rectangular surface in the front is the PV module. The vessels at the back are the ones where the oxygen and hydrogen gas are collected.

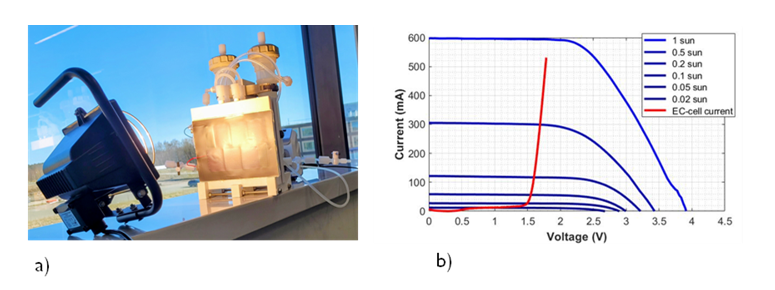

Fig.4.3: a) the PV-integrated electrolyzer set-up under operation with a light source in the front; b) the output curves of the PV module (blue) under different illumination intensities, and of the electrolyzer element (red)

The operation of this PV-integrated electrolyzer system is tested under different illumination intensities, as represented in Fig 4.3a. The output curves of the PV module under different calibrated simulated solar light are given in the graph in Fig 4.3b, together with the operations curve of the electrolyzer. It can be seen that the electrolyzer can remain operational under a wide range of light intensities, from full 1 sun illumination even down to 0.05 sun.

Summary

In conclusion, a close integration of PV solar modules directly coupled with an electrolyzer element has been successfully demonstrated, thanks to an advanced novel design of the electrolyzer element. A broad operational range under different illumination intensities has been realized with this set-up, allowing to reduce impact of variation in solar illumination under real-world operation conditions. This should result in a high amount of effective operational hours in field operation, even when clear sky isn’t guaranteed over the whole day, like typical in a climate as we know in Belgium.

Contact Information

If you have any questions, please don't hesitate to reach out to maarten.houlleberghs [at] kuleuven.be (Maarten Houlleberghs) (KU Leuven) or tom.aernouts [at] imec.be (Tom Aernouts) (imec-imomec).

Work Package 5: Demonstrator H2O/CO2 reduction

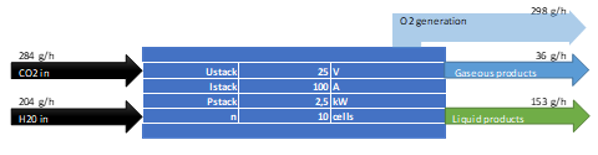

Work package 5 deals with the design and construction of a demonstrator plant that is capable of converting CO2 into valuable chemicals. Direct electrochemical reduction of CO2 offers a great way to shave off power peaks in electricity grids dominated by renewable energy such as wind and solar. Electricity is used directly to reduce CO2 at the cathode. The anodic reaction is in most cases the oxidation of water to oxygen. Formic acid and methanol were the designated chemical for electrochemical reduction. Typically, formic acid forms preferably in aqueous electrolytes (i.e. dissolved CO2), methanol rather than in gaseous systems (i.e. humidified CO2).

Based on the simplified process flow diagram a more detailed process scheme of the balance of plant (BoP) was drawn. From this detailed P&ID a complete list of components is created and this marks the start of procurement and finally the assembly of the full pilot plant. To date (September 2021) a high-cube 20ft container is prepared with a customized rack to install all the components, such as tanks, condensors, heating, cooling, piping, instrumentation, etc. During the coming weeks and months the construction will be finalized and the pilot system will be tested on-site for functional control and checking all safety features are in place. Once this is completed, the pilot can be deployed on any industrial site where a CO2 source and electricity is available. The future looks green.

Contact information

If you have any questions, please don't hesitate to reach out to pieterjan.debergh [at] vito.be (J)joost.helsen [at] vito.be (oost Helsen) (VITO).

Work Package 6: Comparative analysis for other countries

A comparison of status, trends, evolutions in neighbouring countries

Methodology

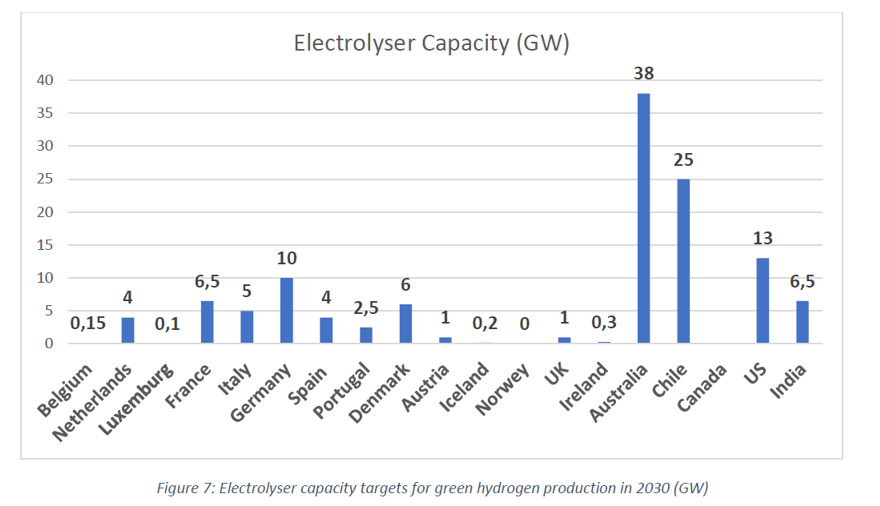

Hydrogen strategies of both neighbouring countries as well as relevant countries for future hydrogen import to Belgium have been monitored and analysed. Next to a number of EU countries, i.e. Belgium, The Netherlands, Luxemburg, France, Italy, Germany, Spain, Portugal, Danmark, Austria, Iceland, Norway, UK and Ireland, a number of non-EU countries has been analysed, i.e. Australia, Chile, Canada, US and India.

For each country systematic analysis has been set up, discussing ambitions and targets regarding production, import, storage, pipelines, usage in chemicals & steel sectors, in transport on road, water and aviation and in the built environment.

Results & conclusions

The different countries position themselves as either hydrogen producers/exporters or as importer/hubs.

Next to local production, especially for the countries in North-West Europe, there is also a plan for import of hydrogen from countries with cheap renewable energy.

Many countries such as Australia, Chile, Spain, Portugal, etc. do not have important plans, since they have access to vast renewable energy sources and hence, not only they can meet their local hydrogen demand but also they can export hydrogen to other countries, especially to North-West European countries.

Several agreements (MoU’s) for hydrogen import and export among different countries have been made during the past years.

Mapping of activities & perspectives for Power-to-X in countries with low cost renewables

Methodology

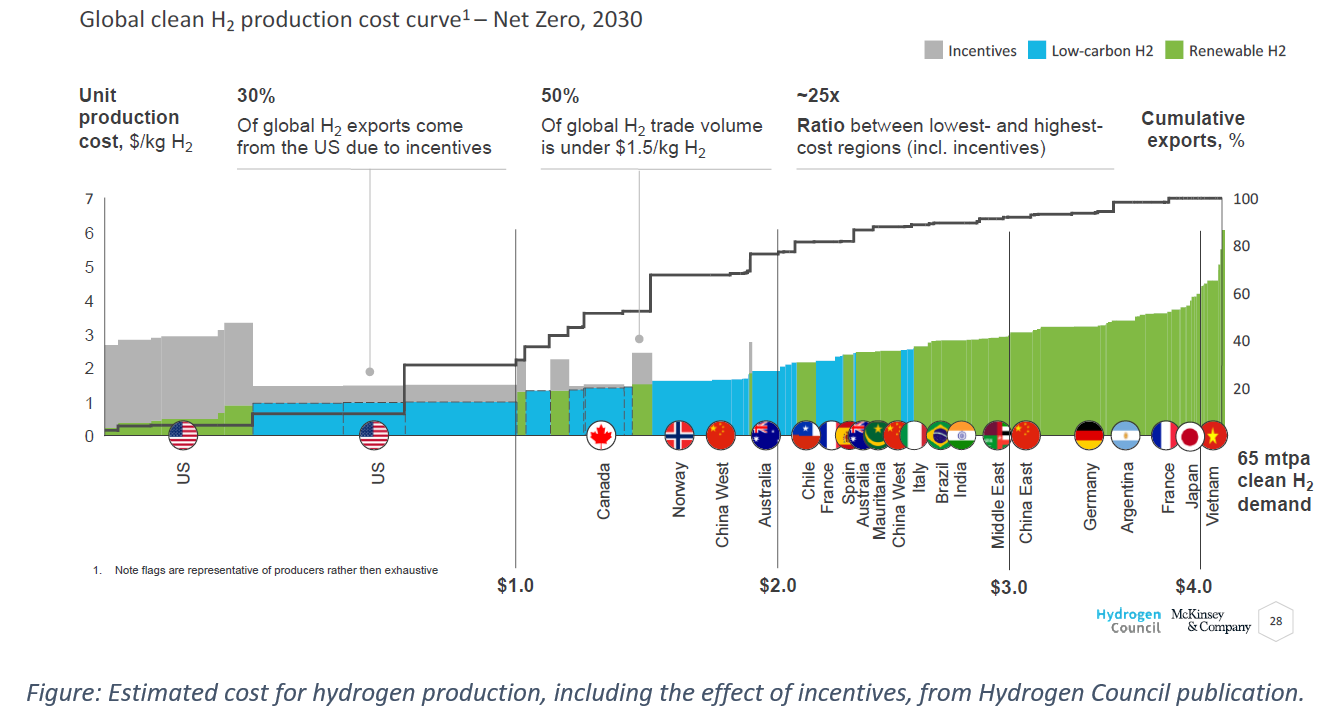

A literature study has been conducted. Several publications of a.o. Irena and the Hydrogen Council (McKinsey) analyse the geopolitical aspects of future hydrogen (& derivative) production. Hydrogen production cost estimates have been calculated by several studies and resulting expected hydrogen flows have been predicted. Even if the calculated prices have been contested for being unrealistically low, the price difference estimates are valuable.

Results & conclusions

A large number of publications has been analysed.

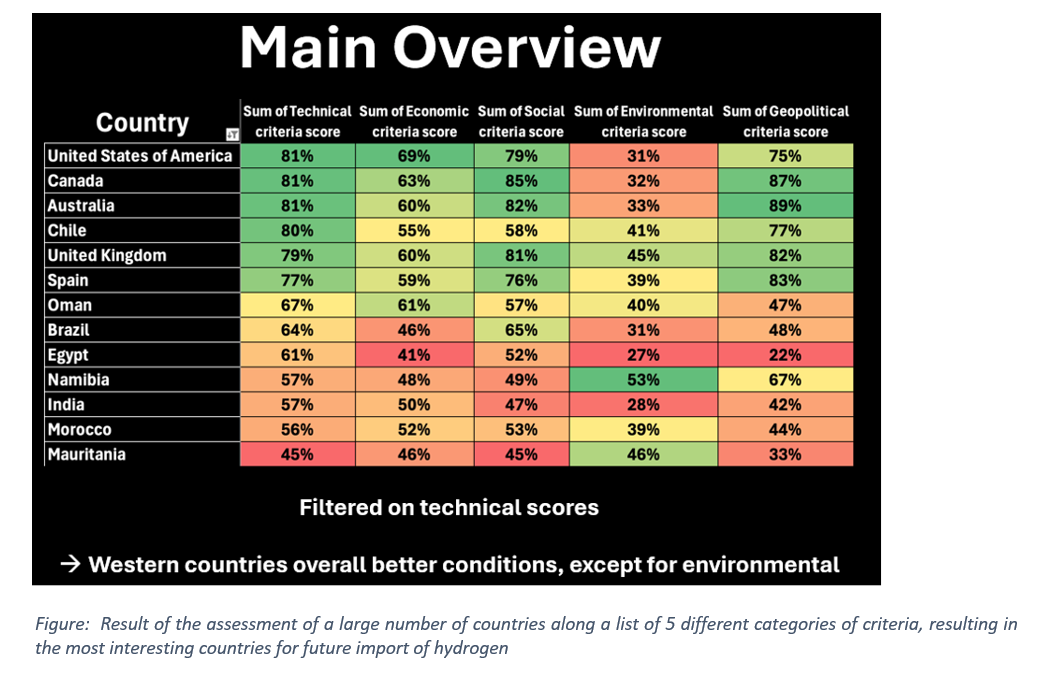

To establish import channels with a certain country, not only the availability of renewable energy sources is important but also the ability to build transport and storage infrastructure in that country, to install a supportive framework for permitting and certification and the availability of a skilled population.

An overview of the most important geopolitical aspects that might influence hydrogen project development and international trade have been deduced from a number of international studies.

To assess countries that have a potential to supply hydrogen and/or derivatives to Belgium, we have developed an assessment tool for the scoring of countries. A set of 24 criteria has been composed, in five categories, that can regularly be updated (most data are available on public websites).

|

Technical |

Economic |

Social |

Environmental |

Geo-political |

|

(TI1) # Full load hours renewable energy wind & solar (hydro or geothermal) |

(EI1) Credit rating |

(SI1) Government expenditure on education, total (% of GDP) |

(EVI1) Environmental Performance Index (Score 0-100): |

(GPI1) Political Stability Index (-2,5 for lowest governance ; 2,5 for highest) |

|

(TI2) Installed capacity RE / total energy demand |

(EI2) Interest rate |

(SI2) Educational Level, at least Bachelor's or equivalent, population 25+, total (%) (cumulative) |

(EVI2) Natural Disaster Risk Index |

(GPI2) Corruption Perceptions Index (CPI) (higher score is less corrupt) |

|

(TI3) Nautical distances to Belgium (or land-distances in case of pipeline) |

(EI3) Inflation, GDP Deflator |

(SI3) Human Development Index (1 for best, 0 for worst) |

(EVI3) Water Stress Index |

(GPI3) Government Efficiency Index (-2,5 for least and 2,5 for most efficient) |

|

(TI4) Hydrogen export potential (Potential for renewable energy – estimated domestic use) |

(EI4) Corporate tax rate |

(SI4) Healthcare score |

(EVI4) Change in Forest Area (%): |

(GPI4) Fragile States Index (FSI) (higher indicator score is more fragile) |

|

|

(EI5) Hydrogen strategy with export potential |

|

|

|

|

|

(EI6) Organisation assigned to develop the hydrogen industry |

|

|

|

|

|

(EI7) Are there local incentives for hydrogen production? |

|

|

|

|

|

(EI8) Supportive framework for external investors |

|

|

|

Table: Criteria for assessment tool for countries to score their attractiveness for H2 export to EU/BE

The tool allows to rank countries on the different criteria, as shown in the figure below.

Techno-economical aspects of import vs own production scenarios

Methodology

An inventory of the hydrogen production and supply cost has been made, starting from different key sources, i.e.

- Hydrogen Import Coalition

- European Hydrogen Bank – Results of the 1st call

- Hydrogen Europe LOCH calculator

- First call of H2Global

- Studies from Neighbouring countries for RFNBOs

The demand in Belgium has been estimated based on the REDIII targets for transport & industry.

Results & conclusions

From the assessment of RFNBO demand in Belgium in 2030, based on the REDIII targets and the use in refineries, it is estimated that around 100 kt is needed for industry and transport and an additional 250 kt can be consumed in refineries.

Refineries are therefore a great kick-starter of the development of hydrogen import value chains.

The assessment of the LCOH (levelized cost of hydrogen) shows a rather wide range for domestic and imported hydrogen. The results of the first auction of the Hydrogen Bank show that despite a lack of scale, the hydrogen production cost in the Nordic countries and Iberian Peninsula is the lowest in Europe, with production levels of 5.8 to 7.6 EUR/kg. Assuming an increased scale of production in the future, it could be considered that the 1-1.5 EUR/kg can be gained through technology maturity. Domestic production cost for renewable hydrogen in Belgium is much higher, approximately in the range of 9- 11 EUR/kg.

The developments of the hydrogen backbone are therefore crucial for Belgium in order to gain access to hydrogen produced in the North and the South of Europe. This is also true for hydrogen that is competitively produced in North Africa, that would be supplied to a pipeline system that is connected to the European Hydrogen Backbone either in Spain or Italy.

The Hydrogen Import Coalition but also the results of the first auction of H2Global indicate that the levelized cost of hydrogen from prime hydrogen exporting countries (Oman, Chile) should be in the range of 4.5 – 5 EUR/kg landed at the Belgian ports.

Analysis of international connections within EU for power-to-x

Methodology

The announced infrastructure development plans – including pipelines and import terminal -of Belgium and the neighbouring countries have been analysed.

Results & conclusions

Comparison with neighbouring countries an recommendations for Belgium

Beside Belgium, the Netherlands and Germany have clear ambitions and strategies for hydrogen imports, other than France who doesn’t see itself playing in hydrogen imports (yet). Germany and the Netherlands have advanced plans and measures to stimulate the development of hydrogen import value chains and it is well recommended for Belgium to follow the pace that these countries are setting. For its imports by ship, Germany as a major demand centre for hydrogen is looking at neighbouring countries to supply hydrogen through their ports to Germany. The development plans of critical infrastructures (storage, crackers, backbone) in the Netherlands and Belgium are therefore very important.

Based on the current plans of the HNOs, it is foreseen that Belgium is the first country in North-West Europe that can connect a large European port to the large German demand centres for the production of steel and chemicals.

Hence, the alignment between the Belgium hydrogen backbone and the German Kernnetz is key and can be as early as 2029. In that case the OGE connection needs to be established 2 years earlier than currently anticipated. It also shows that the support for the development of the Belgian hydrogen backbone must be prioritised as Belgium can lock-in significant amounts of transport cross-border capacity prior to e.g. the Netherlands.

The timing of import terminals in Belgium is well in line with the planning of the hydrogen backbone. The Belgian terminals would already have capacity available as early as 2028 with a significant expansion in 2029. Also here it can be concluded that Belgium is anticipated to lead to way to provide hydrogen to Germany with the expected establishment of ammonia storage capacity by 2029. The development of these terminals should therefore be supported to ensure that Belgium is ready by 2029 as the hydrogen gateway to Germany.

Contact information

If you have any questions, please don't hesitate to reach out to isabel.francois [at] waterstofnet.eu (Isabel François) (Waterstofnet) or michel.honselaar [at] waterstofnet.eu (Michel Honselaar) (Waterstofnet).

Main references

https://www.irena.org/publications/2022/Jan/Geopolitics-of-the-Energy-Transformation-Hydrogen (2022)

https://www.irena.org/Publications/2024/Sep/Shaping-sustainable-international-hydrogen-value-chains (2024)

Global trade in green hydrogen derivatives: Trends in regulation, standardisation and certification (IRENA 2024)

https://hydrogencouncil.com/en/global-hydrogen-flows/ (2022)

https://hydrogencouncil.com/en/the-africa-hydrogen-opportunity/ (2024)

Water for hydrogen production (IRENA 2023)

https://www.waterstofnet.eu/_asset/_public/H2Importcoalitie/Waterstofimportcoalitie-1.pdf

https://www.waterstofnet.eu/_asset/_public/H2Importcoalitie/Belgium-as-a-hydrogen-importhub_web_singlepage-presentation.pdf

Work Package 7: Valorisation potential, market analysis and enabling conditions

Work Package 7 (WP7) of the PROCURA project investigates how integrating climate-friendly technologies affects entire value chains, especially regarding circularity and consumer-facing sectors. By linking technical advances to economic and policy outcomes, WP7 supports the transition to a climate-neutral industrial system in Belgium and Europe.

WP7.1: Process Integration and Carbon Management

Technology Database:

WP7.1 launched the INDUSTRIAL CLIMATE FRIENDLY TECHNOLOGY DATABASE (V6), evaluating 98 technologies across chemicals, refining, hydrogen, and steel sectors. It covers electrification, hydrogen use, CCUS, alternative feedstocks, process intensification, bio-based solutions, chemical recycling, and benchmarks against incumbent processes. Each entry includes process details, energy and CO₂ metrics, costs (OPEX/CAPEX), TRL, and references. The database is considered one of the more comprehensive in Europe for climate-friendly industrial options.

Dissemination: The publicly database is available in pdf and xls format. The results have been shared with industrial, NGO and academic and governmental stakeholders.

Polymer-Oriented Carbon Model:

A new model was developed to assess carbon management in polymer value chains—especially relevant for EU carbon accounting and CCU policy. Unlike typical life cycle assessments, this model tracks carbon through multiple recycling loops, showing how long carbon remains stored in products before eventual atmospheric release. The model introduces a “half-life” metric for carbon in materials, simplifying complex recycling scenarios for policymakers.

Key Findings:

Even with advanced recycling and CCU, substantial carbon loss to the atmosphere occurs over timeframes shorter than that of atmospheric CO₂ residence. This stresses the importance of extending material lifetimes and minimising downgrading in plastics. The findings have informed EU policy discussions (e.g., DG Clima) and were shared with industry stakeholders.

Dissemination: The model, scientific article and supplementary information are available via open access Journal articles. The results have been disseminated at scientific fora, in particular via the CAPTURE research coalition. The results have also been presented to the European Commission and industrial stakeholders.

WP7.2: Value Chain Analysis—Consumer and Policy Impacts

Value Chain Modelling:

WP7.2 rebuilt material flow models for automotive steel, PET packaging, and fertilisers at higher resolution. The focus: how the costs of climate-friendly production (CAPEX/OPEX) pass through the value chain to affect end-user prices.

Results:

◦ Green steel adds just 0.8–4% to car prices.

◦ Green polymers increase premium soft drink prices by 2–5% and low-cost variants by 5–15%.

◦ These impacts are moderate but higher than earlier estimates due to improved modelling detail; they may be larger in countries with lower purchasing power.

Policy Insights:

To unlock markets for climate-friendly materials, demand-side tools like clean materials standards or green public procurement are needed alongside supply-side instruments (e.g., EU ETS). Fiscal policies (like VAT reductions for green products) could offset small consumer price increases while supporting industry transition. These findings align with the EU’s recent Clean Industrial Deal proposals on clean material standards.

Dissemination: An open access journal article will after acceptance be published in scientific journal. The results have been disseminated at scientific fora, in particular via the CAPTURE research coalition. The results have also been presented to the European Commission and industrial stakeholders. The results have been used as part of initiatives on public procurement and clean materials standards.

WP7.3: Policy Impact and Valorisation

Policy and Valorisation Publications:

Two main policy outputs synthesise PROCURA results:

• A policy paper (click to read) detailing investment, infrastructure, innovation, and integration (“4i-s”) challenges for deploying CCUS/H₂ roadmaps in Belgium.

• Valorisation insights exploring future R&D, technology deployment, and Belgium’s potential as an EU hub for hydrogen/CO₂ markets. (Dissemination via final report procura report)

Contact information

If you have any questions, please don't hesitate to reach out to Tomas.Wyns [at] vub.be (Tomas WYNS) (VUB).

List of Publications

• Van der Perre, S. and Wyns, T., 2023, Industrial climate friendly technology database report (pdf) – publicly available

• Van der Perre, S. and Wyns, T., 2023, Industrial climate friendly technology database data (xls) – publicly available

• Van der Perre, s. and Wyns, T. 2023, Carbon management model (xls) freely available on request for academics and policy makers

• Stijn Van der Perre, Oleksii Mynko, Kevin M. Van Geem, Tomas Wyns, Modelling of carbon flows in the value chain of packaging plastics in the context of sustainable carbon management, Sustainable Production and Consumption, Volume 49, 2024, Pages 12-27,ISSN 2352-5509, https://doi.org/10.1016/j.spc.2024.06.002.

• Stijn Van der Perre, Oleksii Mynko, Kevin M. Van Geem, Tomas Wyns, Modelling of carbon flows in the value chain of packaging plastics in the context of sustainable carbon management, Sustainable Production and Consumption, Volume 49, 2024, Supplementary material (https://www.sciencedirect.com/science/article/pii/S2352550924001611)

• Wyns, T. and Khandekar, G., 2024, Value chain price impact for consumers of climate friendly industrial technologies (automotive and PET packaging) – Forthcoming (submitted article available on request)

• Wyns T. and Khandekar, G., 2025 , Operationalising Belgium’s 2050 net-0 emissions Transition – policy insights from PROCURA roadmap. (Publicly available)